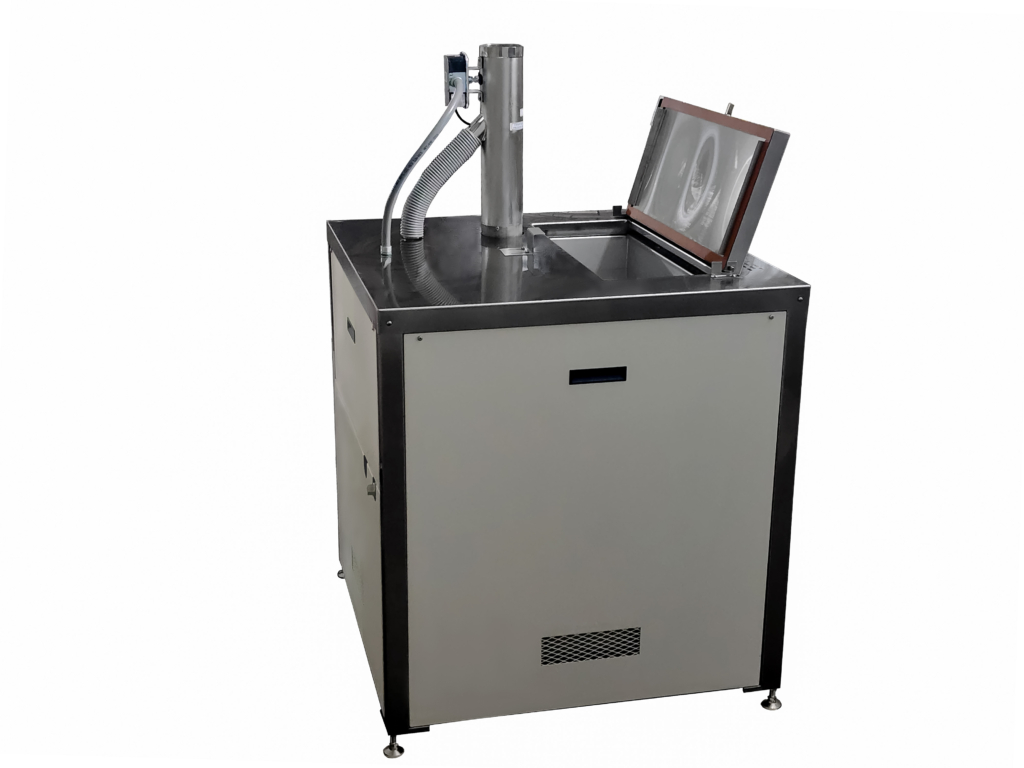

SMT Wastewater Evaporators

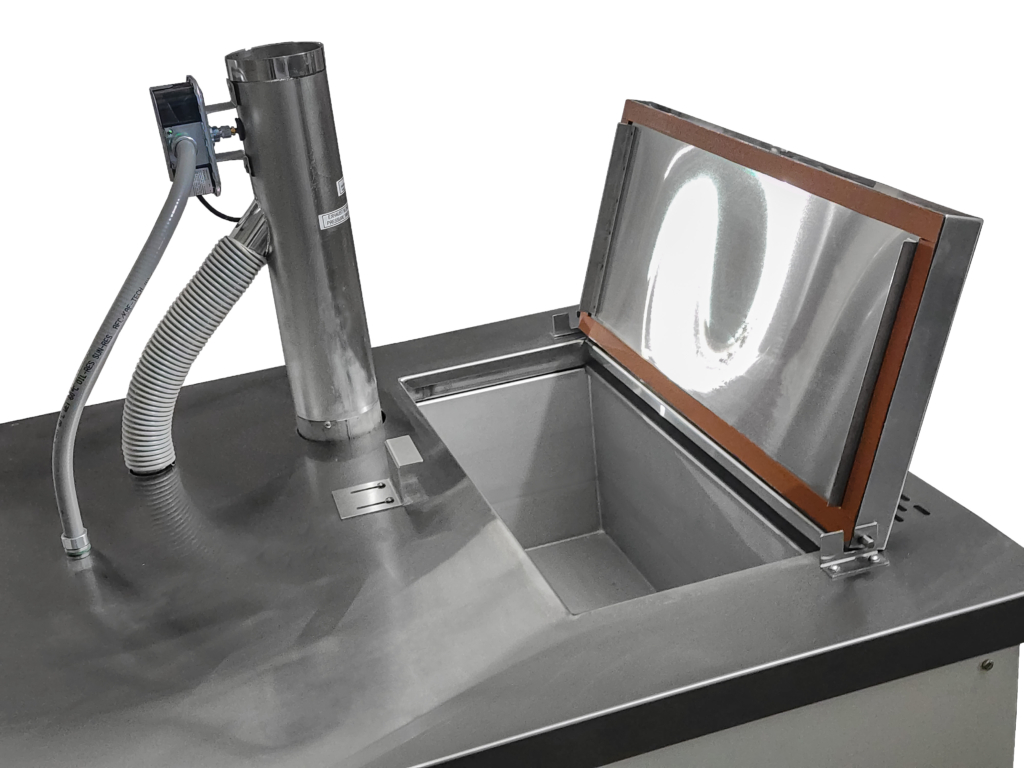

Reservoir Tank Gauge

Control Panel

Stainless Steel Construction

Exhaust Stack

Ask Smart Sonic

about SMT Wastewater Evaporation

Smart Sonic Evaporators evaporate the wastewater from the stencil cleaning process. The wastewater is reduced so that hundreds of gallons of liquid wastewater are turned into just a few pounds of solids or a few gallons of concentrated liquid, thus providing significant savings on disposal costs.

The Model EZ-0 Wastewater Evaporator is Smart Sonic’s exclusive design for operation with any Smart Sonic Stencil Cleaner. “EZ-0” stands for “easy maintenance and zero discharge” because it processes the wastewater in a separate thermostatically-controlled chamber making routine maintenance easier and more efficient, like the Model SE-1, nothing is discharged to drain and the construction is 100% stainless steel.

- Automated Evaporation

- Reduces Costs of Liquid Waste Disposal

- Stainless Steel Construction

- Thermal Jacket for Precise and Even Heating

- Evaporates at 3-5 GPH

- 440-R Detergent is Safe for Evaporation

Air Pressure Sensor

Wash Solution Inlet from Stencil Cleaner

Pump to Transfer Wastewater Solution from Stencil Cleaner

Stainless Steel Heating Chamber

Rubber Seal

Sliding Latch

Power Switch

Start Button

Emergency Stop Button

Temperature Control

Functions Menu

Air Intake Vent

Smart Sonic Model EZ-0 Operations and Features

Smart Sonic Evaporators are the ideal piece of equipment to handle SMT Wastewater. The Model EZ-0 transfers the wastewater from the cleaning process and stores it in the wastewater reservoir waiting to be evaporated. Then, the Model EZ-0 transfers the wastewater into the evaporation chamber where the solution is heated to about 140 degrees.

The heating chamber is lined with a Thermal Jacket and filled with Heat Transfer Fluid. This acts as a double boiler, where the transfer oil reduces hot spots and increases the safety of the heating process. The Model EZ-0 provides even, radiant heat for precise temperature control.

The water vapor is vented out of the exhaust, thus leaving solder pastes and other solids behind. It can be evaporated into a highly concentrated form of liquid waste or into solid waste for safe disposal. The Model EZ-0 will typically evaporate 3 – 5 gallons per hour depending on relative humidity.

Smart Sonic Evaporators reduce the cost of handling large volumes of liquid hazardous waste. Plus, evaporators cost far less than the equivalent reverse osmosis or ion exchange filtration systems required for handling the same amount of wastewater. Unlike costly filtration systems, there is no effluent left for drain disposal.

Evaporation is safe when using Smart Sonic’s 440-R Detergent because it contains No Volatile Organic Compounds. Other detergents may contain volatile chemicals that are not suitable for evaporation. Please contact Smart Sonic if you have questions or concerns about evaporating with other detergents.

Model EZ-0 comes equipped with high and low level probes to ensure the evaporator does not overfill the wastewater reservoir. It comes standard with a built-in exhaust blower for up to 15′ duct run to vent outside. Longer runs can be accomplished and may require an additional blower which should be sized and installed by an HVAC professional.

The control panel allows the evaporator to be fully automatic, and it is able to operate unattended with any Smart Sonic Stencil Cleaner. The control panel will maintain the desired temperature, and the system can automatically transfer the wastewater from the Smart Sonic Stencil Cleaner to the evaporator. Also, the evaporator is equipped with alerts and warnings to ensure safe and reliable evaporation.

If you have questions about Model EZ-0 or SMT wastewater evaporation, please contact Smart Sonic.

Model EZ-0 Maintenance and Operation

The Model EZ-0 is ergonomically designed for easy clean-out. Once the Model EZ-0 is finished evaporating, simply lift the lid, and empty the solids from the heating chamber. This eliminates potential liability associated with industrial drain disposal because there is “zero liquid discharge” and eliminates the long-term liability of transporting and disposing of liquid hazardous waste.

The Model EZ-0 has a thermal jacket design that uses heat transfer oil. Over time, all heat transfer oils degrade. If the evaporator has difficulty maintaining the required operating temperatures, this could mean that the heat transfer fluid has degraded substantially. Smart Sonic provides various heat transfer oils for the Model EZ-0 depending on your local safety and environmental standards.

Heat Transfer Oil

Smart Sonic provides a complete turnkey solution for Stencil Cleaning. While other companies only provide one phase of the stencil cleaning process, Smart Sonic ensures that you will achieve effective ultrasonic cleaning with a powerful, but environmentally safe detergent to clean all solder pastes.

Ultrasonic Stencil Cleaning

Smart Sonic offers a wide array of ultrasonic equipment, from fully automatic stencil cleaners to semi-automatic stencil cleaners.

Smart Sonic Stencil Cleaners are able to clean any type of solder paste from any fine pitch stencil, at the same time its low power density is safe for cleaning misprinted PCBs and pallets. Its low-temperature cleaning conserves energy and protects stencils from heat distortion and adhesive failure.

All Smart Sonics Stencil Cleaners are able to communicate with an EnviroGuard System or a Smart Sonic Evaporator. This provides for a more automated and environmentally friendly Closed-loop Stencil Cleaning System.

SMT Detergent

Smart Sonic’s 440-R SMT Detergent is the workhorse of the Smart Sonic Process. 440-R is an effective chemistry for cleaning all types of solder paste.

More importantly, 440-R does not contain any Volatile Organic Compounds (Zero-VOC), which means that Smart Sonic is able to treat the wastewater through evaporation or through resin filters.

Other SMT detergents contain volatile compounds which are hazardous to evaporate or require more complex wastewater filtration.

Water Treatment

Smart Sonic provides two methods for treating SMT wastewater. Our most popular method is with the Model EZ-0 and the Model SE-1 evaporators. Wastewater is heated and evaporated through an exhaust duct. After the water is evaporated, you can easily dispose of the remaining solids.

Smart Sonic offers wastewater treatment through carbon and resin filters with our EnvrioGuard System. Our filter will catch any solder paste or harmful chemicals, and it can provide an additional source for Deionized (DI) water. This method is more popular where our clients don’t have a suitable means to exhaust vapor for an evaporator or have limited access to DI water.